It is the beginning of a new year, which means it is time to inspect your vehicle lifts to make sure everything is in perfect working order. But how do you truly know everything is in tip-top shape? Read below and we’ll get you started!

1. Have Your Lift ALI-Inspected

With every vehicle lift, the most important thing you can do is make sure your lift is inspected by an ALI-certified inspector. If you are unfamiliar with ALI (Automotive Lift Institute), I suggest reading my recent article all about them. Having this routine inspection can help with finding common lift issues, such as cable erosion and other defects that prevents your lift from safely operating.

You can start off by going to the Find an Inspector page and you will be directed to certified technicians in your area. If your business is in a rural area, try refining your search to a nearby town or city for best results.

Chances are that if you purchased equipment from DEVON, you had it installed by the fine team at 1Source Lifts & Equipment. The 1Source team can perform maintenance, service, and inspection on your vehicle lifts.

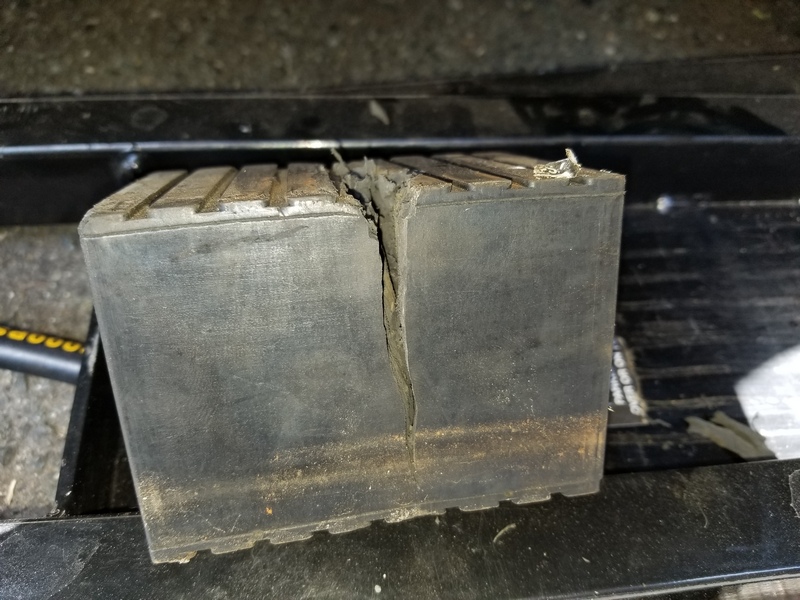

2. Replace Rubber Blocks

One item that tends to wear out quickly over time are the rubber blocks that sit on the vehicle lift arms. These rubber blocks are normally used for low-rise lifts, some rolling pit jacks, and some in-ground lifts to prevent rocker panel covers and/or running boards from being damaged when lifting a vehicle.

Of course, being DEVON, we sell these in different sizes, depending on your needs!

3. Routine Inspections by Staff

When your staff recognizes the benefits of performing these seemingly mundane tasks, everyone wins. Create a daily, weekly and monthly checklist for your auto equipment to ensure the safety of your employees and customers. Getting in the groove of checking for malfunctions and operational errors will be your company’s saving grace!

In Conclusion

It is always a great idea to have your vehicle lift inspected as often as possible. Create a checklist for you and your employees to follow to ensure issues are caught as quickly as possible. Getting in the habit of checking for issues every day, week, and month will greatly increase your bottom line and the working function of your equipment.

« Back to Blog